Ryan Cash

UAMCC Associate Member

How Do I find the Right Nozzle for My Pressure Washer? Which Tip Should I use? What Does Orifice Size mean? How do I Choose the Right Surface Cleaner?

Knowing which size nozzle to use for your surface cleaner or pressure wand can be very confusing, especially for new contractors. Usually when we first get into this industry, we just use whatever spray tips came with our machine. And that will work to some degree, but if you want to maximize your effectiveness you really need make sure that everything is properly set up.

I'm going to break down the 5 Main Considerations in Choosing the Right Spray Tip for your machine.

______________________________________________________________________________________________________________________

1) Choosing right surface cleaner is the first step in making sure your tools are working for you.

Choose your surface cleaner based on the GPM (Gallons Per Minute) of your machine. This can be found in your user manual but almost always also printed somewhere on your machine.

The general rule of thumb is that for every 1 GPM, you can have 4" of surface cleaner.

Although this tends to be the sweet spot for most machines, it’s not a hard rule. So make sure to check with the manufacturer or dealer for questions about your specific machine if you’re not getting the performance you think you should.

______________________________________________________________________________________________________________________

2) Choosing the Right Spray Pattern is the next consideration when looking for the correct nozzles/spray tips for your machine.

The most common fan patterns are 0, 15, 25, 40, and 65 degrees. The higher the number, the wider the fan pattern.

A 0-Degree (Red) nozzle sprays in a thin, jet pattern and yields the highest impact on the surface you’re cleaning. All of the force is concentrated on a small spot so it cleans a very small area at once but has the full force of the machine behind that small area. This spay pattern should be used VERY sparingly (if at all) and has a high risk of damaging what you are spraying. To make this practical for cleaning, the “turbo nozzle” was created to spin the 0-degree tip extremely fast so that a larger area can be cleaned. However, there is still a lot of potential for damage because of the nature of the 0-degree tip.

The 15-Degree (Yellow) tip offers a slightly larger spray pattern but still has a high force of impact. It’s much harder to blend and can cause some cleaned surfaces to look uneven. Take caustion as to not damage the material that you’re cleaning. It can be an effective spot cleaner.

The 25-Degree (Green) tip tends to be the most popular as the fan pattern. The spray pattern is larger so it allows easier blending and uniform cleaning. It still has enough force behind it to effectively clean while minimizing risk. This is the most common tip used in surface cleaners as well. It’s wider than the 15 degree tip, making it easier to wash different substrates.

The 40-Degree Tip (White) tip is the most gentle of the standard spray tips. It will most commonly be used in one of four general circumstances.

As you continue to increase the angle (40, 65..) the water becomes more and more diffused, making it too “gentle” to effectively clean. These wider tips are most commonly used for rinsing or cleaning delicate substrates

______________________________________________________________________________________________________________________

3) Knowing What Pressure You Want. The next step in choosing the right nozzle will be understanding what you are cleaning and what the adequate pressure is for that surface. If you’re just blasting everything with full power, you’re potentially causing damage. Let’s break down each surface

Asphalt Roofs and All Types of Siding: 500-600 PSI Max soft wash. Most soft wash pumps put out around 100 or so PSI but anything under 600 won’t cause damage. The key to this work is the chemistry, not the pressure!

Residential Concrete: 2500-3000 PSI Max. Most residential concrete is rated right around 2500 Psi so anything over this pressure can etch the concrete and cause damage. One important thing to note is the age of the concrete. Most contractors try to avoid concrete that’s been poured within the last 2-3 years. Newer concrete is much more susceptible to damage and may require alternative methods/lower pressure to clean without damage.

Wood: 800-1000 PSI Max. Many contractors prefer a soft-wash approach to wood using various chemicals (Sodium Hypochlorite, Peroxide or Sodium Metasilicate are the main 3); However, you can clean wood with pressure. Most residential decking or fences will typically be a softer wood like Cedar, Pine, or Fir. These dent and damage easily so 800 PSI is usually about where you can max out and be safe. More expensive hardwoods (Teak, Ipe, Mahogany) can handle a little bit more pressure (1000 PSI) but you need to be careful because these woods are much more expensive.

Tile Roofs: 1200 PSI Max (Usually). Most contractors will opt to soft wash clay tile and concrete roofs. However, typically manufacturers will say pressure washing is an acceptable way to clean them if you don’t exceed 1200 PSI. If you decide to go this route, check the manufacturer’s websites to verify as you can damage tiles and seal coats with too high of pressure.

Composite Decking: 3000 PSI Max. This one is tricky though. The age of the product and manufacturer will determine this 100% and every one is different! Most contractors opt to soft wash composite decking but it’s important to verify with the manufacturer as to the best way to clean specific composites without causing damage. Older composites won’t hold up to high pressure.

Asphalt: 1500 PSI Max. No degreasers (Unless formulated specifically for asphalt) and no Heat. Asphalt is very soft and susceptible to damage. Many contractors turn down asphalt cleaning because of it’s difficulty. SH will typically leave residue as well. Asphalt will need to be rinsed a lot! Start soft and build up to a max of around 1500 PSI

Brick: 2500 PSI Max. Typically a mix of soft wash and pressure washing will result with the best finished product. A turbo nozzle can be used and will help remove some of the deeper staining. As always, start soft and increase pressure based on the condition of the brick.

Commercial Concrete: 4000 PSI Max. Usually commercial concrete is cleaned between 3000 and 4000 PSI, with 3500 being the sweet spot. Degreasers and Hot water will aid tremendously and are considered essential by many contractors.

Tennis Courts: 1500 PSI max. Be careful of damaging paint and the court. Not recommended to use a surface cleaner as it’s very easy to leave lap lines and cause bad results. A mixture of soft washing with a 1500 PSI rinse/clean up is the most common and safest method.

______________________________________________________________________________________________________________________

4) Choosing the right Orifice Size is vital in getting the most out of your machine. The orifice size is essentially how large the hole is in the nozzle.

A larger orifice will allow water to flow through more easily and result in a lower pressure. A smaller orifice will constrict the water leaving the machine, resulting in higher pressures. Understand that your pump is designed to push out the same amount of water regardless of the size of the hole it’s pushing it through (to an extent).

If you have a 5 GPM machine, it will push 5 gallons of water out every minute regardless of how confined it was. If you had a garden hose hooked up to your pump, the water would come out in a very slow, as it’s not constricted at all and can freely flow from the hose. However, if replaced that garden hose with a pressure hose with a very small orifice, it would take tremendous pressure and water speed to get those same 5 gallons of water out in a minute.

Just like using your machine to determine the size of your surface cleaner, you will also use it to determine what size tips you should use in your cleaner, based on what pressure you are looking to achieve for your specific purpose.

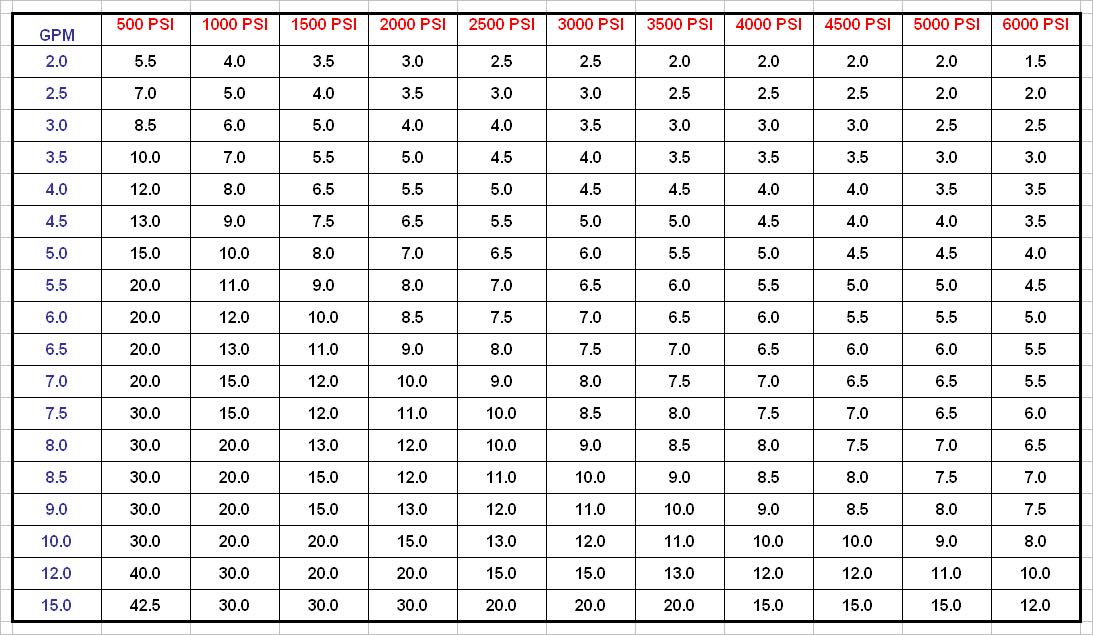

Use the following chart to determine which size orifice you should pick.

Keep in mind, this is the correct orifice size if you were to use a single spray nozzle (like on a spray gun). If you plan to be using a surface cleaner with two spray nozzles you need to take that into consideration. The easiest way to do this is to divide the GPM in half when you’re looking at the chart (Since the flow rate will be divided between to two nozzles)

Example: The Rooftec XCS500 runs roughly 5 GPM at 2500 PSI max. If I were running a surface cleaner with two nozzles, half of the water flow would be traveling to the end of each nozzle. So I would be putting out roughly 2.5GPM from each nozzle at 2500 PSI. I follow the chart and find that the correct orifice size for each nozzle would be: (3.0). However, if I were to run a single nozzle spray wand with the same machine I would use the full 5 GPM and 2500 PSI specs to find that I should run a 6.5 nozzle.

The smaller the number, the more the water is constricted and the higher the PSI.

______________________________________________________________________________________________________________________

5) Picking and Purchasing the correct nozzle is the last step in the process. Now that we’ve determined the correct size of the surface cleaner, the correct angle for the spray pattern, the correct pressure, and the correct orifice size; how do you know what spray tip to buy?

If you look closely at the nozzles you’ll see a number that looks something like: “25025”

The first part of the number is the angle of the fan tip. So 25025. The first 25 Designates that it’s a 25 degree fan tip. If you wanted a 0 degree tip it would be 0025. Or a 65 degree tip would be 65025.

The second part of the number is the orifice size. So 25025. The 025 designates that it is a 2.5 sized orifice. Similarly at 25065 would be a 6.5 orifice.

So when picking a nozzle for your wand/surface cleaner, use your machines GPM and PSI to determine orifice size, and then use the desired spray pattern and orifice size to choose the right nozzle.

______________________________________________________________________________________________________________________

5) All Nozzle are Not Created Equal.

One final thing to keep in mind is that different nozzles from different manufacturers will wear differently.

The most important thing to look at is how deep the orifice is inset into the nozzle. While running a surface cleaner, often times rocks and other debris will bounce around inside the spinner head and can come in contact with the nozzles as they’re spinning.

Any time your surface cleaner isn’t performing as expected, let the nozzles be the first thing that you check!

Knowing which size nozzle to use for your surface cleaner or pressure wand can be very confusing, especially for new contractors. Usually when we first get into this industry, we just use whatever spray tips came with our machine. And that will work to some degree, but if you want to maximize your effectiveness you really need make sure that everything is properly set up.

I'm going to break down the 5 Main Considerations in Choosing the Right Spray Tip for your machine.

______________________________________________________________________________________________________________________

1) Choosing right surface cleaner is the first step in making sure your tools are working for you.

Choose your surface cleaner based on the GPM (Gallons Per Minute) of your machine. This can be found in your user manual but almost always also printed somewhere on your machine.

The general rule of thumb is that for every 1 GPM, you can have 4" of surface cleaner.

- 2.5 GPM – 10 inch (possibly up to 12)

- 3.0 GPM – 12 inch

- 4.0 GPM – 16 Inch

- 5.0 GPM – 20 inch

- 8.0 GPM – 32 inch

Although this tends to be the sweet spot for most machines, it’s not a hard rule. So make sure to check with the manufacturer or dealer for questions about your specific machine if you’re not getting the performance you think you should.

______________________________________________________________________________________________________________________

2) Choosing the Right Spray Pattern is the next consideration when looking for the correct nozzles/spray tips for your machine.

The most common fan patterns are 0, 15, 25, 40, and 65 degrees. The higher the number, the wider the fan pattern.

A 0-Degree (Red) nozzle sprays in a thin, jet pattern and yields the highest impact on the surface you’re cleaning. All of the force is concentrated on a small spot so it cleans a very small area at once but has the full force of the machine behind that small area. This spay pattern should be used VERY sparingly (if at all) and has a high risk of damaging what you are spraying. To make this practical for cleaning, the “turbo nozzle” was created to spin the 0-degree tip extremely fast so that a larger area can be cleaned. However, there is still a lot of potential for damage because of the nature of the 0-degree tip.

It can be used as a long distance shooter tip for rinsing high gutters. It can be used to cut drainage points in grass to control water run-off or for more industrial applications (removing deep engrained gravel/grease off of heavy machinery like excavators and bulldozers).

The 15-Degree (Yellow) tip offers a slightly larger spray pattern but still has a high force of impact. It’s much harder to blend and can cause some cleaned surfaces to look uneven. Take caustion as to not damage the material that you’re cleaning. It can be an effective spot cleaner.

Typically only used on unpainted surfaces. It works great for things like gum removal (especially paired with hot water), heavy grease on machinery and other applications where high pressure is needed. They can be used in a surface cleaner (a much better choice than the cheaper 0-degree tips that come in many spinners) but in general, a 25-degree tip is more effective.

The 25-Degree (Green) tip tends to be the most popular as the fan pattern. The spray pattern is larger so it allows easier blending and uniform cleaning. It still has enough force behind it to effectively clean while minimizing risk. This is the most common tip used in surface cleaners as well. It’s wider than the 15 degree tip, making it easier to wash different substrates.

The jack-of-all trades spray tip. Due to it’s larger fan pattern, it is much easier to blend and can be used (with caution) on wood surfaces. It’s larger spray pattern allows it to be an adequate nozzle for rinsing dirt off of cleaned surfaces. A 25-degree nozzle with the correct orifice size will generally give you the best clean with a surface cleaner and minimize lap lines.

The 40-Degree Tip (White) tip is the most gentle of the standard spray tips. It will most commonly be used in one of four general circumstances.

- When you’re worried about damage to the substrate. This tip can typically be used with around 800-900 PSI for wood or other delicate surfaces that a stronger blast may damage.

- It’s good for rinsing. After applying chemical, this spray pattern is capable of rinsing a large area at once.

- It can make a good “water broom”. After cleaning a driveway, Switch to the 40-degree tip and use it to rinse off the remaining dirt/debris that has gathered on the surface.

- Use this to pre-soak/pre-treat surfaces. At a distance this can also be used to gently pre-soak plants/other areas to prevent damage from chemical overspray.

As you continue to increase the angle (40, 65..) the water becomes more and more diffused, making it too “gentle” to effectively clean. These wider tips are most commonly used for rinsing or cleaning delicate substrates

______________________________________________________________________________________________________________________

3) Knowing What Pressure You Want. The next step in choosing the right nozzle will be understanding what you are cleaning and what the adequate pressure is for that surface. If you’re just blasting everything with full power, you’re potentially causing damage. Let’s break down each surface

Asphalt Roofs and All Types of Siding: 500-600 PSI Max soft wash. Most soft wash pumps put out around 100 or so PSI but anything under 600 won’t cause damage. The key to this work is the chemistry, not the pressure!

Residential Concrete: 2500-3000 PSI Max. Most residential concrete is rated right around 2500 Psi so anything over this pressure can etch the concrete and cause damage. One important thing to note is the age of the concrete. Most contractors try to avoid concrete that’s been poured within the last 2-3 years. Newer concrete is much more susceptible to damage and may require alternative methods/lower pressure to clean without damage.

Wood: 800-1000 PSI Max. Many contractors prefer a soft-wash approach to wood using various chemicals (Sodium Hypochlorite, Peroxide or Sodium Metasilicate are the main 3); However, you can clean wood with pressure. Most residential decking or fences will typically be a softer wood like Cedar, Pine, or Fir. These dent and damage easily so 800 PSI is usually about where you can max out and be safe. More expensive hardwoods (Teak, Ipe, Mahogany) can handle a little bit more pressure (1000 PSI) but you need to be careful because these woods are much more expensive.

Tile Roofs: 1200 PSI Max (Usually). Most contractors will opt to soft wash clay tile and concrete roofs. However, typically manufacturers will say pressure washing is an acceptable way to clean them if you don’t exceed 1200 PSI. If you decide to go this route, check the manufacturer’s websites to verify as you can damage tiles and seal coats with too high of pressure.

Composite Decking: 3000 PSI Max. This one is tricky though. The age of the product and manufacturer will determine this 100% and every one is different! Most contractors opt to soft wash composite decking but it’s important to verify with the manufacturer as to the best way to clean specific composites without causing damage. Older composites won’t hold up to high pressure.

Asphalt: 1500 PSI Max. No degreasers (Unless formulated specifically for asphalt) and no Heat. Asphalt is very soft and susceptible to damage. Many contractors turn down asphalt cleaning because of it’s difficulty. SH will typically leave residue as well. Asphalt will need to be rinsed a lot! Start soft and build up to a max of around 1500 PSI

Brick: 2500 PSI Max. Typically a mix of soft wash and pressure washing will result with the best finished product. A turbo nozzle can be used and will help remove some of the deeper staining. As always, start soft and increase pressure based on the condition of the brick.

Commercial Concrete: 4000 PSI Max. Usually commercial concrete is cleaned between 3000 and 4000 PSI, with 3500 being the sweet spot. Degreasers and Hot water will aid tremendously and are considered essential by many contractors.

Tennis Courts: 1500 PSI max. Be careful of damaging paint and the court. Not recommended to use a surface cleaner as it’s very easy to leave lap lines and cause bad results. A mixture of soft washing with a 1500 PSI rinse/clean up is the most common and safest method.

______________________________________________________________________________________________________________________

4) Choosing the right Orifice Size is vital in getting the most out of your machine. The orifice size is essentially how large the hole is in the nozzle.

A larger orifice will allow water to flow through more easily and result in a lower pressure. A smaller orifice will constrict the water leaving the machine, resulting in higher pressures. Understand that your pump is designed to push out the same amount of water regardless of the size of the hole it’s pushing it through (to an extent).

If you have a 5 GPM machine, it will push 5 gallons of water out every minute regardless of how confined it was. If you had a garden hose hooked up to your pump, the water would come out in a very slow, as it’s not constricted at all and can freely flow from the hose. However, if replaced that garden hose with a pressure hose with a very small orifice, it would take tremendous pressure and water speed to get those same 5 gallons of water out in a minute.

Just like using your machine to determine the size of your surface cleaner, you will also use it to determine what size tips you should use in your cleaner, based on what pressure you are looking to achieve for your specific purpose.

Use the following chart to determine which size orifice you should pick.

- Find the GPM in the left column that corresponds to the GPM of your machine

- Following that row, scan to find the PSI you want to achieve. Max out with the PSI listed for your pump.

- The resulting box will show you the correct orifice size that should be used for your machine.

Keep in mind, this is the correct orifice size if you were to use a single spray nozzle (like on a spray gun). If you plan to be using a surface cleaner with two spray nozzles you need to take that into consideration. The easiest way to do this is to divide the GPM in half when you’re looking at the chart (Since the flow rate will be divided between to two nozzles)

Example: The Rooftec XCS500 runs roughly 5 GPM at 2500 PSI max. If I were running a surface cleaner with two nozzles, half of the water flow would be traveling to the end of each nozzle. So I would be putting out roughly 2.5GPM from each nozzle at 2500 PSI. I follow the chart and find that the correct orifice size for each nozzle would be: (3.0). However, if I were to run a single nozzle spray wand with the same machine I would use the full 5 GPM and 2500 PSI specs to find that I should run a 6.5 nozzle.

The smaller the number, the more the water is constricted and the higher the PSI.

______________________________________________________________________________________________________________________

5) Picking and Purchasing the correct nozzle is the last step in the process. Now that we’ve determined the correct size of the surface cleaner, the correct angle for the spray pattern, the correct pressure, and the correct orifice size; how do you know what spray tip to buy?

If you look closely at the nozzles you’ll see a number that looks something like: “25025”

The first part of the number is the angle of the fan tip. So 25025. The first 25 Designates that it’s a 25 degree fan tip. If you wanted a 0 degree tip it would be 0025. Or a 65 degree tip would be 65025.

The second part of the number is the orifice size. So 25025. The 025 designates that it is a 2.5 sized orifice. Similarly at 25065 would be a 6.5 orifice.

So when picking a nozzle for your wand/surface cleaner, use your machines GPM and PSI to determine orifice size, and then use the desired spray pattern and orifice size to choose the right nozzle.

______________________________________________________________________________________________________________________

5) All Nozzle are Not Created Equal.

One final thing to keep in mind is that different nozzles from different manufacturers will wear differently.

The most important thing to look at is how deep the orifice is inset into the nozzle. While running a surface cleaner, often times rocks and other debris will bounce around inside the spinner head and can come in contact with the nozzles as they’re spinning.

If the orifice is flush with the tip of the nozzle, any contact with flying debris can damage the tip and cause it to not spray properly. This damage typically results in uneven cleaning and lap lines on large surfaces.

To help mitigate this, choose nozzles that have the orifice inset into the nozzle. The extra steel built up around the orifice will protect it from flying debris and allow it to last longer in your surface cleaner.

To help mitigate this, choose nozzles that have the orifice inset into the nozzle. The extra steel built up around the orifice will protect it from flying debris and allow it to last longer in your surface cleaner.

Any time your surface cleaner isn’t performing as expected, let the nozzles be the first thing that you check!