Ryan Cash

UAMCC Associate Member

How is the Rooftec system different from other systems on the market?

What is the best exterior cleaning system?

What are the positives and negatives of down streaming?

What system should I get for soft washing?

Today I want to break down and take a look at the top 5 types of exterior cleaning systems. This guide will list the general theory of each system, as well as it’s positives and negatives. While I clearly have my bias and preference, this guide will hopefully explain the differences between each type of system and help you make a better, choice in which one you should purchase.

There are 5 general categories of systems on the market:

The first category of exterior cleaning system is what’s known as Down Streaming.

Downstream injection is a means of applying chemicals with the use of a pressure washer by use of the Venturi Effect. The injection happens on the down-stream side of the pump (after the pressure pump)

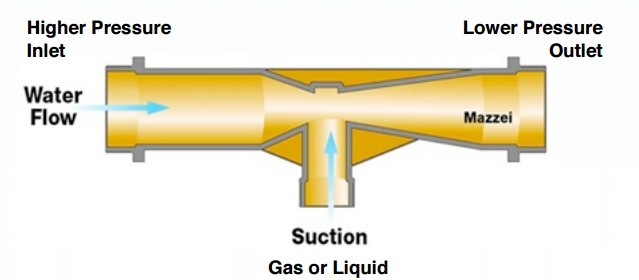

Venturi injectors work on the principle of differential pressure. Water enters the venturi at a higher pressure than it exits. The difference in the entry and exit pressures creates a vacuum at the suction port on the side of the venturi. The bigger the difference, the greater the vacuum and therefore the efficiency of the mixing.

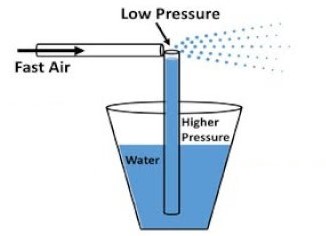

To see a simplified version of how this works, take two drinking straws and drop one of them into a cup of water. Take the second straw and hold it perpendicular to the first. Blow into the end of the straw and you’ll see water rise out of the cup into the air stream. (This is also a fun way to surprise younger kids with some water in their face at a restaurant)

For exterior cleaning, this requires a few things. You need a Venturi (Down-stream) injector, and you need an orifice on your spray gun that reduces the outgoing pressure. Using a high pressure nozzle won’t supply you with the pressure differential needed to draw up chemicals, so for down streaming, you'll hear contractors call these "soap tips"

Another good example of this type of chemical injection is the X-Jet. It is essentially a down-stream injector that is placed on the end of the spray gun rather than next to the pump. The benefit of the x-jet is that it's able to draw a higher volume of chemical and get you a stronger mix than a standard DS injector will pull.

What are the Pro’s of Down-streaming?

What are the Con’s of Down-streaming?

The second category of exterior cleaning system are the 12V pumps.

These systems run off of a 12 volt battery and are technically a form of upstream chemical injection (Chemical is injected in line, before the pump). Brands of 12V pumps include Delevan, Remco, Everflo, Northstar, and many others.

Contractors who run these types of systems fall into one of two categories: Batch Mixing, and Blend Mixing.

When batch mixing, a 12v system will rely on a large chemical tank where chemicals are pre-mixed based on what is being cleaned. For roof cleaning, for example, the chemical tank might be ½ water and ½ Sodium Hypochlorite. A suction hose from the pump is then placed into the batch tank and the chemical mix is drawn up through the pump and pushed out to the spray gun.

Blend Systems rely on the same principle, but rather than pre-mixing to a desired chemical concentration, the system will have both a water tank and a chemical tank. There is a suction hose in each tank and the pump draws up chemical in ratios set with valves on a manifold that are mixed in line and then cycled through the pump. The benefit of these systems is that you can change your solution ratios on the fly and you don't have to estimate how much chemical you will use before a job starts.

What are the Pro’s of 12V Systems?

What are the Con’s of 12V Systems?

The third category of exterior cleaning system are the Air Diaphragm Pumps.

These use compressed air as a power source. Top models of air diaphragm pump include Flojet and All-Flo. The compressed air is shifted from one chamber to the other by a linked shaft that allows the chambers to move simultaneously. This back-and-forth motion forces liquid out of one chamber and into the discharge piping while the other chamber is being filled with liquid at the same time.

Air diaphragm pumps can draw from a batch mix, much like a 12V, but are almost always set up with a blend manifold with variable mixing options.

What are the Pro’s of an Air Diaphragm System?

What are the Con’s of an Air Diaphragm Systems?

The next category of exterior cleaning systems are the Gas Roof Pumps.

Gas roof pumps are very similar to air diaphragm pumps in that they’re typically constructed of chemical resistant polypropylene. The most commonly used Gas Roof pump is the AR45. Rather than being powered by an air compressor, the AR45 is powered by a gas engine. These diaphragm pumps create suction on the inlet hose and can easily draw chemical from a blend manifold.

Gas roof pumps are very similar to air diaphragm pumps in that they’re typically constructed of chemical resistant polypropylene. The most commonly used Gas Roof pump is the AR45. Rather than being powered by an air compressor, the AR45 is powered by a gas engine. These diaphragm pumps create suction on the inlet hose and can easily draw chemical from a blend manifold.

What are the Pro’s of a Gas Roof Pump?

What are the Con’s of a Gas Roof Pump?

The final category of exterior cleaning systems are Upstream Pressure Pumps.

I understand that I am biased, since this is my system, but bias isn’t necessarily a bad thing as long as you’re still fair. First: a basic explanation. The Rooftec system is an upstream injection exterior cleaning machine that uses a tri-plunger general pump. What makes this system unique is that chemical injection happens before the pump (similar to a 12V, air diaphragm, or gas roof pump) but the pump is capable of both high and low pressure.

The 5GPM TS2212 pressure pump runs off of a 14HP gas engine that drives the pump to create suction on the inlet hose. The pump draws Bleach (SH), Water, and Surfactant through a manifold prior to the pump and then pressurizes it to the desired setting (100-2500PSI). The operation is fairly simple and runs in a similar fashion to a standard pressure washer.

What are the Pro’s of the Rooftec XCS500?

What are the Con’s of the Rooftec XCS500?

So finally, the question, Which system is the best/which system should you buy?

Honestly, that’s going to depend on what exactly you need and expect out of a cleaning system. Are you doing big commercial jobs? Are you primarily doing residential work? Do you Pressure Wash only? Do you soft wash only? Do you clean roofs or do you only clean siding?

All these questions are contributing factors in your decision.

If you want the best, all-in-one system for residential cleaning, the Rooftec XCS500 is the winner here.

However, it may not be the best system for everyone. Maybe you don’t need high pressure? Maybe you don’t need low pressure? Maybe your focus is commercial work or parking garage cleaning? Maybe you only clean siding and never think about cleaning roofs also. Take time to learn each system and evaluate it based on your needs.

If you think the Rooftec system is would work best for you, check our our distributor’s site or shoot me an email and I’d be happy to talk to you more about it!

r.cash@legendbrands.com

What is the best exterior cleaning system?

What are the positives and negatives of down streaming?

What system should I get for soft washing?

Today I want to break down and take a look at the top 5 types of exterior cleaning systems. This guide will list the general theory of each system, as well as it’s positives and negatives. While I clearly have my bias and preference, this guide will hopefully explain the differences between each type of system and help you make a better, choice in which one you should purchase.

There are 5 general categories of systems on the market:

- Down streaming (including X-Jet)

- 12V Electric Pumps

- Air Diaphragm Pumps

- Gas Roof Pumps

- Upstream Pressure Pumps (Rooftec System)

The first category of exterior cleaning system is what’s known as Down Streaming.

Downstream injection is a means of applying chemicals with the use of a pressure washer by use of the Venturi Effect. The injection happens on the down-stream side of the pump (after the pressure pump)

Venturi injectors work on the principle of differential pressure. Water enters the venturi at a higher pressure than it exits. The difference in the entry and exit pressures creates a vacuum at the suction port on the side of the venturi. The bigger the difference, the greater the vacuum and therefore the efficiency of the mixing.

To see a simplified version of how this works, take two drinking straws and drop one of them into a cup of water. Take the second straw and hold it perpendicular to the first. Blow into the end of the straw and you’ll see water rise out of the cup into the air stream. (This is also a fun way to surprise younger kids with some water in their face at a restaurant)

For exterior cleaning, this requires a few things. You need a Venturi (Down-stream) injector, and you need an orifice on your spray gun that reduces the outgoing pressure. Using a high pressure nozzle won’t supply you with the pressure differential needed to draw up chemicals, so for down streaming, you'll hear contractors call these "soap tips"

Another good example of this type of chemical injection is the X-Jet. It is essentially a down-stream injector that is placed on the end of the spray gun rather than next to the pump. The benefit of the x-jet is that it's able to draw a higher volume of chemical and get you a stronger mix than a standard DS injector will pull.

What are the Pro’s of Down-streaming?

- It requires very little expense outside of your normal pressure washing set up ($50-$150)

- They are easy to use and replace

- They provide a strong enough mix to clean most siding

- Quickly switch between down-streaming and high pressure washing with tip changes

- No chemical is running through your pressure pump

What are the Con’s of Down-streaming?

- They typically max out at about 1:10 chemical to water draw rate

- This is not strong enough for roof cleaning

- In order to get a stronger mix, your only option is the X-jet

- A great choice, but can be cumbersome to move around a customer’s property

- Can sometimes result in lots of overspray/atomization of chemical

The second category of exterior cleaning system are the 12V pumps.

These systems run off of a 12 volt battery and are technically a form of upstream chemical injection (Chemical is injected in line, before the pump). Brands of 12V pumps include Delevan, Remco, Everflo, Northstar, and many others.

Contractors who run these types of systems fall into one of two categories: Batch Mixing, and Blend Mixing.

When batch mixing, a 12v system will rely on a large chemical tank where chemicals are pre-mixed based on what is being cleaned. For roof cleaning, for example, the chemical tank might be ½ water and ½ Sodium Hypochlorite. A suction hose from the pump is then placed into the batch tank and the chemical mix is drawn up through the pump and pushed out to the spray gun.

Blend Systems rely on the same principle, but rather than pre-mixing to a desired chemical concentration, the system will have both a water tank and a chemical tank. There is a suction hose in each tank and the pump draws up chemical in ratios set with valves on a manifold that are mixed in line and then cycled through the pump. The benefit of these systems is that you can change your solution ratios on the fly and you don't have to estimate how much chemical you will use before a job starts.

What are the Pro’s of 12V Systems?

- Parts are readily available and can be purchased fairly cheap (if you want to build your own system)

- They are easy to use and replace ($200-$300 for a pump)

- They can provide a strong enough mix to clean virtually any exterior surface or roof

What are the Con’s of 12V Systems?

- 12V pumps are not designed to handle Bleach (SH) and are notoriously unreliable in longevity

- Most contractors will purchase a couple pumps at a time to have as backup

- Will require it’s own set of hoses and hose reels (These usually max out around 70PSI)

- Contractors will need to have a full secondary set up for pressure washing

- Contractors will need to remember to charge their batteries every night

- Or pay to wire the system to their vehicle's battery

The third category of exterior cleaning system are the Air Diaphragm Pumps.

Air diaphragm pumps can draw from a batch mix, much like a 12V, but are almost always set up with a blend manifold with variable mixing options.

What are the Pro’s of an Air Diaphragm System?

- Pumps are typically made from Polypropylene and hold up really well to Bleach (SH)

- They can provide a strong enough mix to clean virtually any exterior surface or roof

- Can be upwards of 10GPM for far distance spraying

- High GPM capabilities make it a great system for commercial cleaning as well

What are the Con’s of an Air Diaphragm Systems?

- Just like other soft wash systems, this will require a whole separate pressure washing system for high pressure cleaning

- Requires additional air compressor to run

- More systems require more maintenance

- Air compressor

- Diaphragm pump

- Pressure Washer

- Can sometimes be difficult to troubleshoot (not always...some systems are fairly straight forward)

- Can be finicky and require precise air pressure to run well

- Due to nature of pump, sometimes you’ll see pulsations in water flow

The next category of exterior cleaning systems are the Gas Roof Pumps.

What are the Pro’s of a Gas Roof Pump?

- Pumps are typically made from Polypropylene and other chemical resistant materials.

- They can provide a strong enough mix to clean virtually any exterior surface or roof

- Typically are upwards of 10-11GPM for far distance spraying and very high flow applications

- High GPM capabilities make it a great system for commercial cleaning

- Some systems can shoot chemical up to 50ft.

- Slightly higher PSI than other systems (up to 250-300PSI)

What are the Con’s of a Gas Roof Pump?

- Many users find them hard to maintain/trace leaks

- Similar to other soft wash systems, this will require a whole separate pressure washing system for high pressure cleaning

- Loudest of the Soft Wash systems available (Gas powered)

The final category of exterior cleaning systems are Upstream Pressure Pumps.

I understand that I am biased, since this is my system, but bias isn’t necessarily a bad thing as long as you’re still fair. First: a basic explanation. The Rooftec system is an upstream injection exterior cleaning machine that uses a tri-plunger general pump. What makes this system unique is that chemical injection happens before the pump (similar to a 12V, air diaphragm, or gas roof pump) but the pump is capable of both high and low pressure.

The 5GPM TS2212 pressure pump runs off of a 14HP gas engine that drives the pump to create suction on the inlet hose. The pump draws Bleach (SH), Water, and Surfactant through a manifold prior to the pump and then pressurizes it to the desired setting (100-2500PSI). The operation is fairly simple and runs in a similar fashion to a standard pressure washer.

What are the Pro’s of the Rooftec XCS500?

- One pump drives both soft washing and pressure washing

- No need for separate systems and hoses

- 100-2500 PSI

- Highly reliable stainless steel pump minimizes downtime caused by pump failures

- Can run a 20” surface cleaner

- Able to reach hot mixes found with other dedicated soft wash systems

- Small footprint able to fit in a standard truck bed

What are the Con’s of the Rooftec XCS500?

- Louder than 12V systems

- Approx. 85 dB (Similar to that of a lawn mower)

- Lower, 5GPM flow not suitable for larger commercial jobs

- Smaller buffer tank may not be immediately sufficient for some well-water homes

So finally, the question, Which system is the best/which system should you buy?

Honestly, that’s going to depend on what exactly you need and expect out of a cleaning system. Are you doing big commercial jobs? Are you primarily doing residential work? Do you Pressure Wash only? Do you soft wash only? Do you clean roofs or do you only clean siding?

All these questions are contributing factors in your decision.

If you want the best, all-in-one system for residential cleaning, the Rooftec XCS500 is the winner here.

However, it may not be the best system for everyone. Maybe you don’t need high pressure? Maybe you don’t need low pressure? Maybe your focus is commercial work or parking garage cleaning? Maybe you only clean siding and never think about cleaning roofs also. Take time to learn each system and evaluate it based on your needs.

If you think the Rooftec system is would work best for you, check our our distributor’s site or shoot me an email and I’d be happy to talk to you more about it!

r.cash@legendbrands.com

Attachments

Last edited: